IMO 2020 Maritime Regulations Could Increase Shipping Costs

October 28, 2019

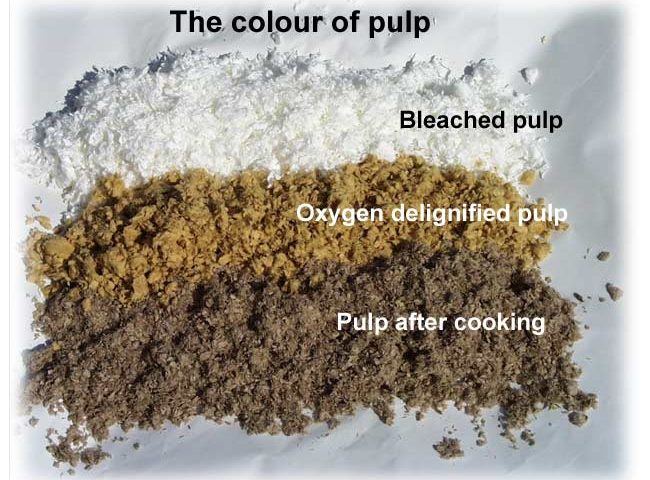

APP Canada to debut new uncoated paper in early 2020

November 13, 2019The objective of pulp bleaching is to produce white pulp. Unbleached pulp is not suitable for manufacturing of high grade of white paper. Since all the processing pulp brightness is very low, especially Kraft pulp. The sulfate pulping process produces comparatively bright chemical pulp, while the others pulping process such as kraft, soda and semi-chemical are produced quite dark pulp. The approximate brightness of unbleached kraft pulp range is 15-30, whereas sulfate pulp range is 50-65. In modern world most of the pulp is manufactured by Kraft pulping process. The pulp is not only made of cellulose and hemicelluloses, but it also contains some impurities which are never completely removed in the pulping process. Inherently, cellulose and hemicelluloses are white in color and don’t contribute to pulp colorization. Impurities like lignin, colored organic matter are predominantly impart color to the pulp. Generally the chromophoric groups of lignin are responsible for this.

Two principal reactions are occurred during the chemical bleaching of pulp. One type of reactions is to solubilization the coloring matter and almost totally removes them. The other type of reactions is to changing the coloring matters to a colorless form by selectively destroy some of the chromophoric groups which is as stable as possible to color and heat.

Bleaching Process adds more brightness to the pulp.

Oxidative mechanisms are believed to convert part of the lignin’s phenolic groups to quinone-like substance that are known to absorb light. Heavy metal ions (e.g., iron and copper) are also known to form colored complexes with the phenolic groups. Extractive materials can contribute to the color of mechanical pulp made from resinous woods.

The pulp brightness is measured by its ability to reflect monochromatic light in comparison to a known standard. To measure the pulp brightness two most widely common processes are Elrepho and ISO method. In Elrepho method the used instrument is Zeiss Elrepho reflectance meter which provides a diffuse light source and standard reflecting surface is magnesium oxide block or snow. If a surface reflects all the applied monochromatic light colors in the same proportions is said to be pure white such as pure cellulose will reflect normal light in its true proportions. Fully bleached sulfite pulp can test as high as 94% Elrepho.

The principal pulp bleaching agents are chlorine, chlorine dioxide, hypochlorite, peroxide, chlorite, oxygen and ozone.

Definition of pulp bleaching: Removal of colored substance or alter the coloring material from chemical pulp to increase its brightness and cleanliness, without deleterious effect on the physical and chemical properties of the pulp.